Sterilisation

Simple and functional processes

AUTOCLAVES

SW PLATINUM

Excellence and Sustainability in Sterilisation

Stern Weber SW Platinum autoclaves combine high performance, efficiency, and eco-friendliness. Their innovative water treatment system minimizes waste and optimizes resources, allowing water reuse and significantly reducing consumption. With just 5 litres of water, up to 50 sterilisation cycles can be completed, making them a sustainable choice for dental practices.

Maximum Water Savings: Treatment of used water

One of the most innovative features of SW Platinum is its water management system, which allows water to be recovered after use and reused in subsequent sterilisation cycles.

• Filtration and Demineralisation: the autoclave is equipped with an integrated demineralisation filter, which allows the equipment to be filled directly with mains water.

• Water Recirculation: thanks to a recirculation filter located in the secondary tank, water is purified after use and reused, allowing up to 50 cycles to be performed with just 5 litres of water.

• Efficiency and Sustainability: this innovative system reduces operating costs and environmental impact, eliminating the need for continuous supply of demineralised water or for centralised water treatment systems.

Thanks to this smart technology, SW Platinum is today the ideal choice for professionals.

Technology, efficiency and sustainability for an optimised practice

Stern Weber SW Platinum autoclaves are the state of the art in sterilisation.

By integrating perfectly into the workflow of a dental practice, they guarantee operational efficiency, safety and sustainability.

• Optimised workflow: the sterilisation process is faster and better organised thanks to the Modular Drying function, which adapts drying times based on load, and to quick cycles that improve the clinic productivity.

• Smart interface and immediate control: the 7” touchscreen display offers an intuitive experience with video tutorials and luminous indicators which, via the integrated LED bar, allow cycle status to be monitored at a glance.

• Advanced connectivity:

SW Platinum's Wi-Fi and Ethernet integration enables remote management and traceability through digital protocols.

The SterilConnect app allows real-time monitoring and notifications, enhancing sterilisation efficiency and workflow in dental practices.

SW PLUS

Efficient and safe sterilisation

Sterilisation is an essential aspect to ensure quality and safety in dental practices.

SW Plus is the autoclave designed to ensure maximum efficiency, easy use and operational reliability.

Thanks to its compact size, installation versatility and advanced technology, it perfectly adapts to the needs of modern clinics.

Featuring an intuitive design with a 5” capacitive touchscreen, SW Plus makes the sterilisation process faster and safer, streamlining the staff's daily work.

Integration with digital traceability and Wi-Fi connectivity systems ensures constant control and optimisation of operations.

Innovation and safety in sterilisation

SW Plus is an advanced autoclave system that enhances dental practice workflows with its technology and safety features. It offers efficient sterilisation with a Modular Drying function, a quick 134°C cycle, and a demineraliser filter for direct water use. The 5” touchscreen and video tutorials simplify management, while Wi-Fi and Ethernet connectivity allow real-time monitoring via the SterilConnect app. MyTrace software ensures traceability by linking sterilised instruments to patients, storing data securely.

Maximum simplicity and guaranteed safety

SW Plus streamlines sterilisation by integrating advanced technology and intuitive management, reducing operation times and enhancing workflow efficiency. It features a Modular Drying function, a demineraliser filter for direct water use, and a user-friendly touchscreen with video tutorials. The system ensures full traceability of sterilisation cycles through MyTrace and offers real-time monitoring via the SterilConnect app, combining innovation, simplicity, and safety for optimal practice management.

SW

The versatile solution for daily sterilisation

Sterilisation is an essential aspect to ensure quality and safety in dental practices.

SW Plus is the autoclave designed to ensure maximum efficiency, easy use and operational reliability.

Thanks to its compact size, installation versatility and advanced technology, it perfectly adapts to the needs of modern clinics.

Featuring an intuitive design with a 5” capacitive touchscreen, SW Plus makes the sterilisation process faster and safer, streamlining the staff's daily work.

Integration with digital traceability and Wi-Fi connectivity systems ensures constant control and optimisation of operations.

Innovation and safety in sterilisation

SW Plus is an advanced system that optimizes processes in modern dental practices. The modular drying function reduces time and optimizes energy. The 134°C cycle lasts 31 minutes. The integrated demineralizer filter uses tap water, monitoring quality. The 5” touchscreen simplifies management. Video tutorials and Wi-Fi/Ethernet connectivity enhance digital integration. The SterilConnect app and MyTrace software ensure real-time monitoring and traceability.

Maximum simplicity and guaranteed safety

SW Plus streamlines sterilisation by integrating advanced technology and intuitive management, reducing operating times and enhancing staff efficiency. It features a Modular Drying function, a demineraliser filter for easy water use, and a 5” touchscreen for simplified operations. The system ensures full traceability with MyTrace and integrates seamlessly into digital workflows via Wi-Fi and Ethernet. Stern Weber's SW Plus combines innovation, simplicity, and traceability, optimizing schedules and ensuring patient safety.

Disinfection

TETHYS H10 PLUS

Tethys H10 Plus is the new thermal disinfector that makes the instrument reconditioning process simple and practical. This innovative device carries out many of the numerous manual tasks typically encountered prior to sterilization, thus reducing personnel workloads and risk. With the Tethys H10 Plus decontamination, washing, thermal disinfection and drying are compacted into one fast automated process.

TETHYS

Without doubt, the answer to obtaining the best results with least effort is provided by the latest series of Tethys washer-disinfectors. These completely automatic devices guarantee perfect cleaning of instruments and the highest standard of disinfection, while ensuring at the same time complete protection for operators and the elimination of any possible procedural errors.

There are 45 cm (Tethys T45), and 60 cm (Tethys D60/T60) versions available.

HMD accessory for Tethys H10

Tethys HMD

Revolutionary Evolution

Thanks to the new HMD, Tethys H10 is now also a handpiece thermal disinfector. This latest accessory makes it possible to wash, thermally disinfect and dry up to 6 instruments (turbines or micromotor handpieces) simultaneously. The HMD is compatible with all Tethys H10, including those that have already been installed. All the user has to do is update the firmware to make the thermal disinfector more complete than ever.

The support can easily be assembled and removed; this allows use of a traditional basket and ensures the Tethys H10 can still perform its original function as an ultrasound thermal disinfector.

With the new handpiece cycle and the dedicated support, a cycle can be completed in just 34 minutes.

This cycle consists of:

- Washing (no ultrasound)

- Thermal disinfection

- Drying

Thermal disinfection effectiveness on external surfaces has been verified as per EN15883-1 and EN15883-2.

Packaging

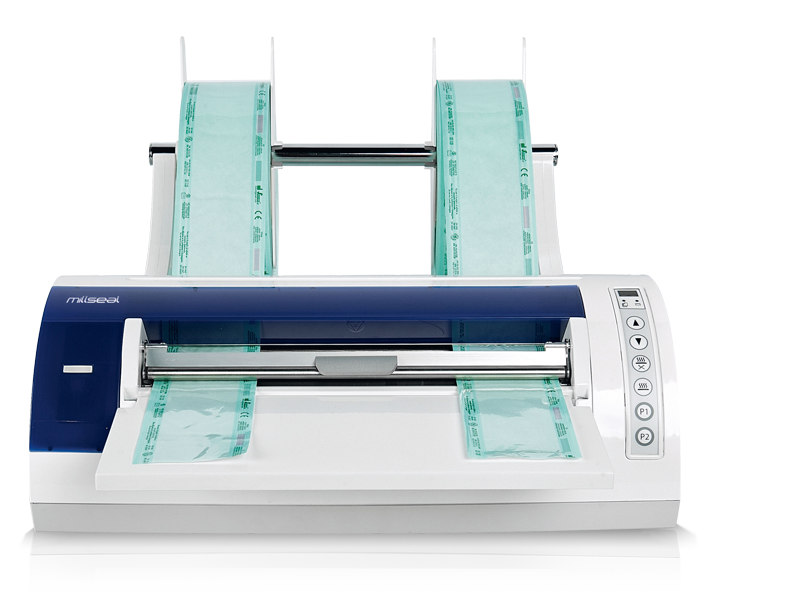

MILLSEAL+ EVO AUTOMATIC

The display shows the length and number of bags. Two-way roller slide system. Cut and first bag seal key. Definitive bag seal key. Programme keys allow 2 different bag lengths to be saved and sealing/cutting tasks to be executed automatically.

MILLSEAL+ MANUAL

Bag length is selected manually, as is the bag cut. To close the bag containing the material ready for sterilisation just press on the sealing lever until the “sealing complete” beep sounds. A positioning systems holds the paper in place to prevent rewinding of the roll after cutting and sealing.

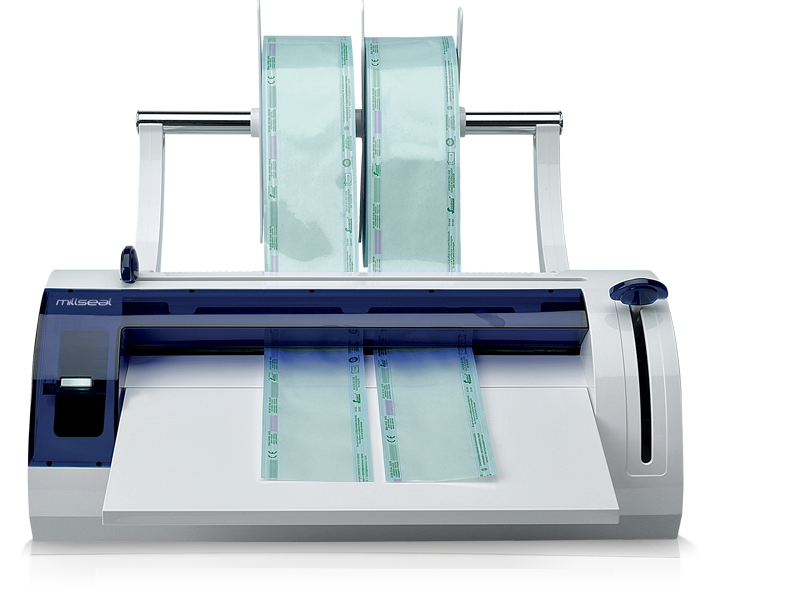

MILLSEAL ROLLING

Roller-type thermal sealer with automatic feed system. Offering medical-standard quality, this unit is ideal for speeding up and optimising sealing of pre-cut bags sealed on 3 sides. A 15 mm sealing band ensures longlasting sterility of bagged instruments. The large display allows the user to view and set working parameters simply and intuitively.

Maintenance of rotary devices

Thalya

Simple maintenance

Thalya is the dentist’s latest ally for effective maintenance of rotary instruments. Simple and userfriendly, it allows perfect lubrication and purge maintenance of turbines and handpieces. To start using the machine just connect to the compressed air feed and the power supply.

Lubrication and purge of 4 instruments in less than a minute

The Thalya cycle consists of three stages:

- Duct purge

- Lubrication

- Excess oil purge

The 4 instruments are treated simultaneously, the entire cycle lasting about 55 seconds.

The Thalya control pad makes interaction with the machine immediate and intuitive. Moreover, users can personalise the duration of the different cycle stages.

Thalya is designed to house any lubricant can (from 200 to 500 ml).

.svg)